Chassis

We offer our customers the following for the “chassis” area:

- Vehicle chassis parts (e.g. longitudinal frame members), also as complete, ready-to-install units with a sheet thickness of up to 12 mm

- Detachable body components and chassis parts such as crossmembers, gusset plates, reinforcements with a sheet thickness of up to 12 mm

- Surface technologies such as zinc-phosphate coating, cathodic dip painting (CDP) and topcoat systems

- Planning, design and manufacturing of production-specific cutting, bending and drawing tools

- Frame pre-assembly, just-in-sequence and module deliveries

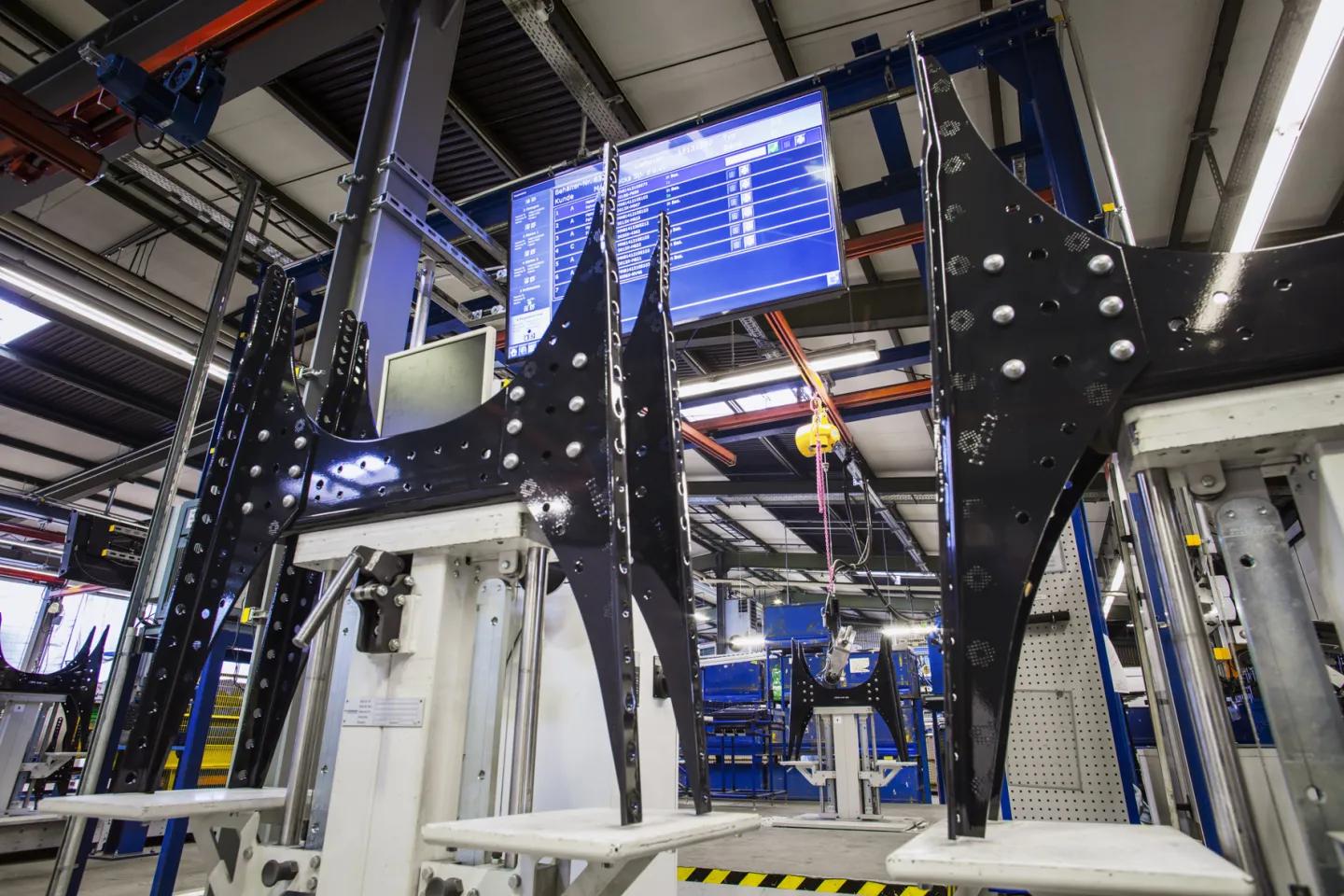

Into quality in a big way

We produce all kinds of detachable body components and chassis parts made from sheets up to 12 mm thick and in material grades up to QStE 700 TM. The range of parts encompasses crossmembers, detachable parts, gusset plates, reinforcements and welded body components for truck frames. We have particular expertise in the joining of pressed parts to form components. In addition to CDP priming, the option exists to use an additional topcoat.

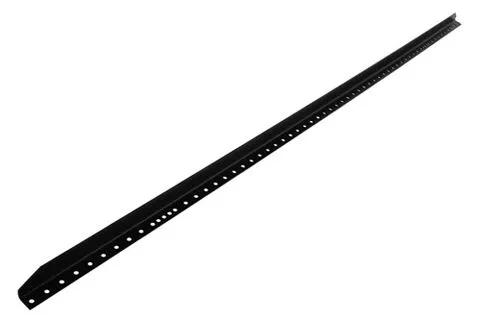

Product group: Longitudinal frame members

For light-, medium- and heavy-duty truck model series, we produce longitudinal frame members made from high-strength materials up to QStE 500 TM and in material thicknesses of up to 10 mm. Longitudinal frame members are available in straight and bent designs and with individual hole patterns. Two large presses with a pressing force of up to 50,000 kN as well as a roll-forming system for rolling the longitudinal members are available for production. The state-of the-art cathodic dip painting system is designed for maximum corrosion protection with zinc-phosphate coating via spraying and cathodic dip painting.

Product group: Detachable frame components

For light-, medium- and heavy-duty truck model series, we produce detachable frame components made from high-strength materials up to QStE 700 TM and in material thicknesses of up to 12 mm. Four press lines, production cells for assemblies and a cathodic dip painting system with pretreatment and cataphoretic immersion priming are available at two locations for production.

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Gustavsburg here.