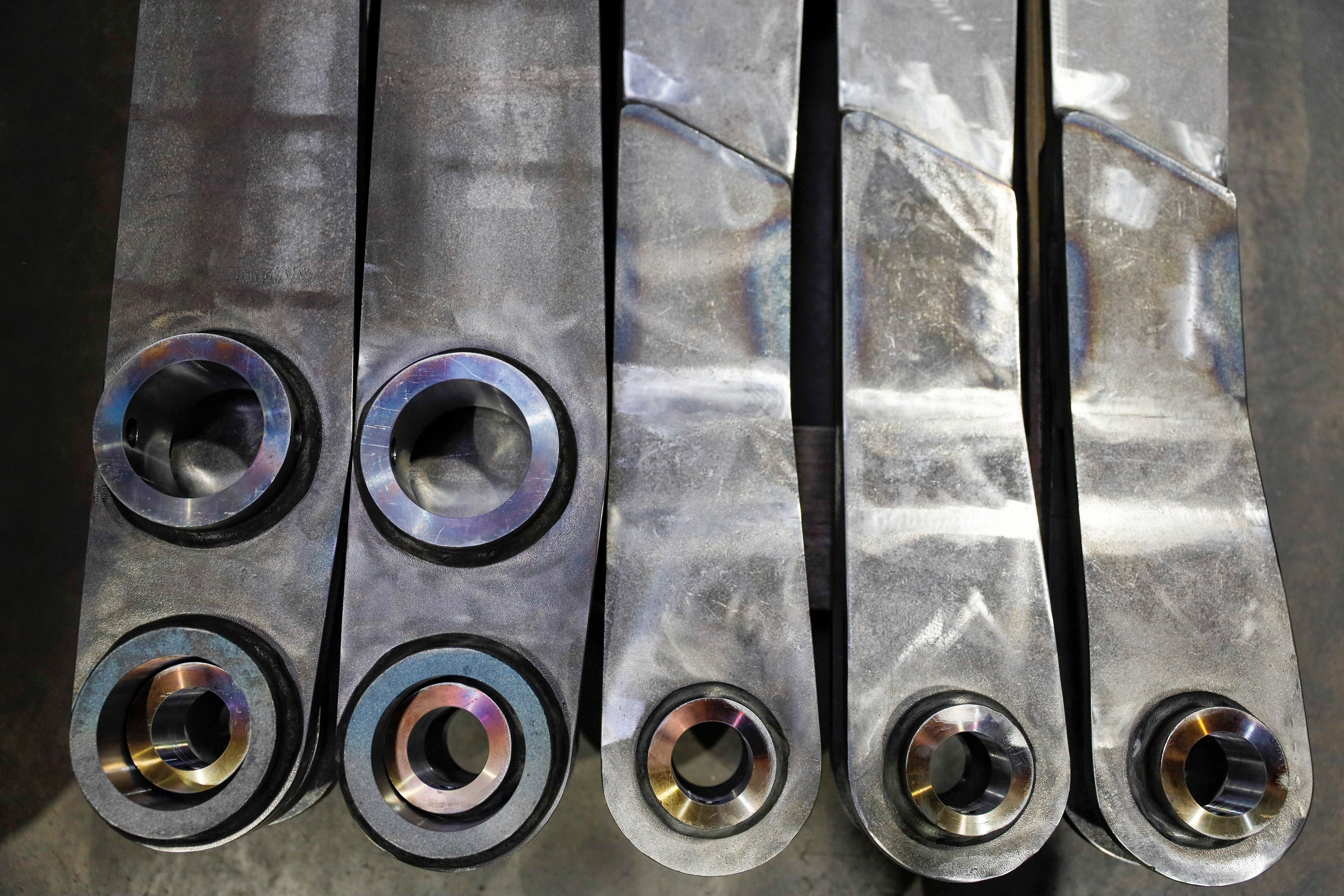

Welded Components

We mainly produce axle-supporting chassis parts with differing degrees of complexity that we deliver directly – in welded assembly and welded component form – to the assembly line. All established robot and manual welding methods (MIG, MAG, TIG) are used and adapted to the material to be welded and customer requirements. Our state-of-the-art facilities guarantee that the customer is provided in each case with the optimal method for a high throughput rate with maximum quality and the lowest possible production costs.

Our range of services covers the following:

- Production of components and replacement parts in low-volume production

- Use of all established robot and manual welding methods (MIG, MAG or TIG)

- Assembly

- Machining

- Just-in-time or just-in-sequence delivery

- Weld-seam test

- Traceability

- Anti-corrosion coating in accordance with customer specification (e.g. cathodic dip painting)

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.