Innovation

Innovation goes hand in hand with customer benefits. We achieve these in close dialogue with our customers with regard to the stated product requirements as well as via close cooperation in our network consisting of competence centres, universities and technology partners. Here we focus above all on two aspects:

- Product Development

- Technology Development

These two development areas allow us to implement new technological approaches in terms of cost efficiency, integration of functions or improved performance in products. At the same time, we challenge ourselves from a technological perspective – to implement ideas from internal product development or to satisfy the requirements of our customers.

The current technological core topics concern the realisation of cost-efficient lightweight solutions that are indispensable for our customers, especially against the background of the current trend of electromobility. We focus both on structural and material lightweight solutions. We view both approaches as decisive in the commercial vehicle sector and are accordingly focusing intensively on the development of new steel lightweight technologies and strategies for the processing of promising lightweight materials.

Our aspiration is clear: We want to shape the future of mobility together in a network consisting of customers, universities and competence centres.

1. Innovation in Product Development

As an established system provider for the commercial vehicle industry, HÖRMANN Automotive develops new solutions for the delivery traffic of tomorrow. In this connection, we see ourselves obliged as a supplier to play our part in achieving CO2-neutral logistics.

The associated challenges for the commercial vehicle sector are immense and motivate us to overcome them together with our partners and customers.

Innovation for heavy-duty commercial vehicles

The influencing factors for innovations in heavy-duty commercial vehicles range for HÖRMANN Automotive from economic lightweight design approaches to function and component integration to new topological vehicle structures.

We are also considering completely new vehicle systems in connection with semitrailers in order to be able to optimally equip ourselves from a technological perspective for the future requirements in heavy-duty commercial vehicles.

Here the synchronous technology development provides us with decisive input in the areas of forming and joining technology for the realisation of innovative structures and systems that differ decisively from the current ladder-type frames with regard to the weight, costs, functionality and the integration of alternative energy carriers.

What guides us here are the customer issues that we see becoming relevant alongside weight, number of variants and costs, in particular against the background of the emission legislation for 2025 and 2030. New solutions are required – for this reason, we are already planning ahead today.

Innovation for light-duty commercial vehicles

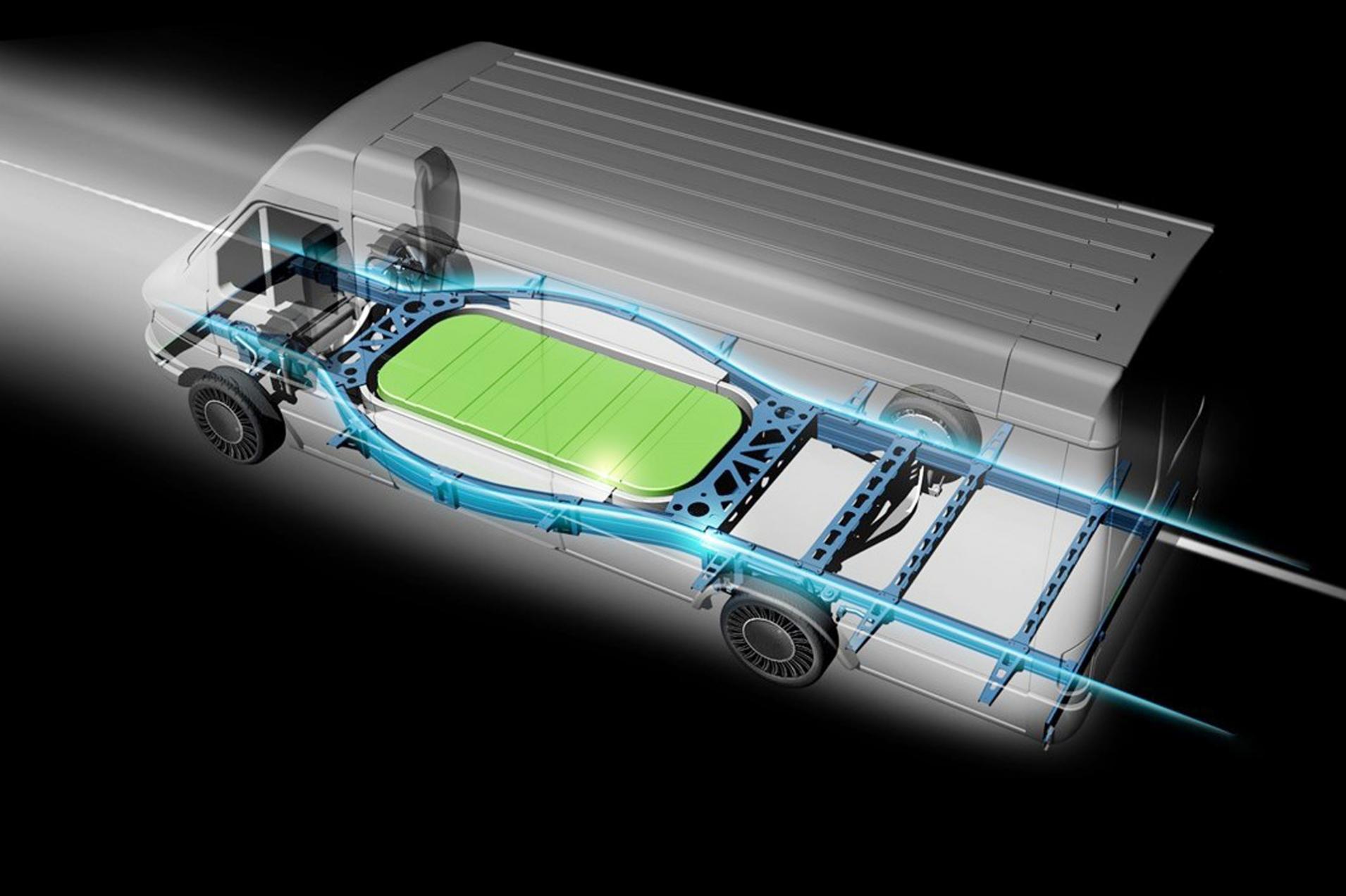

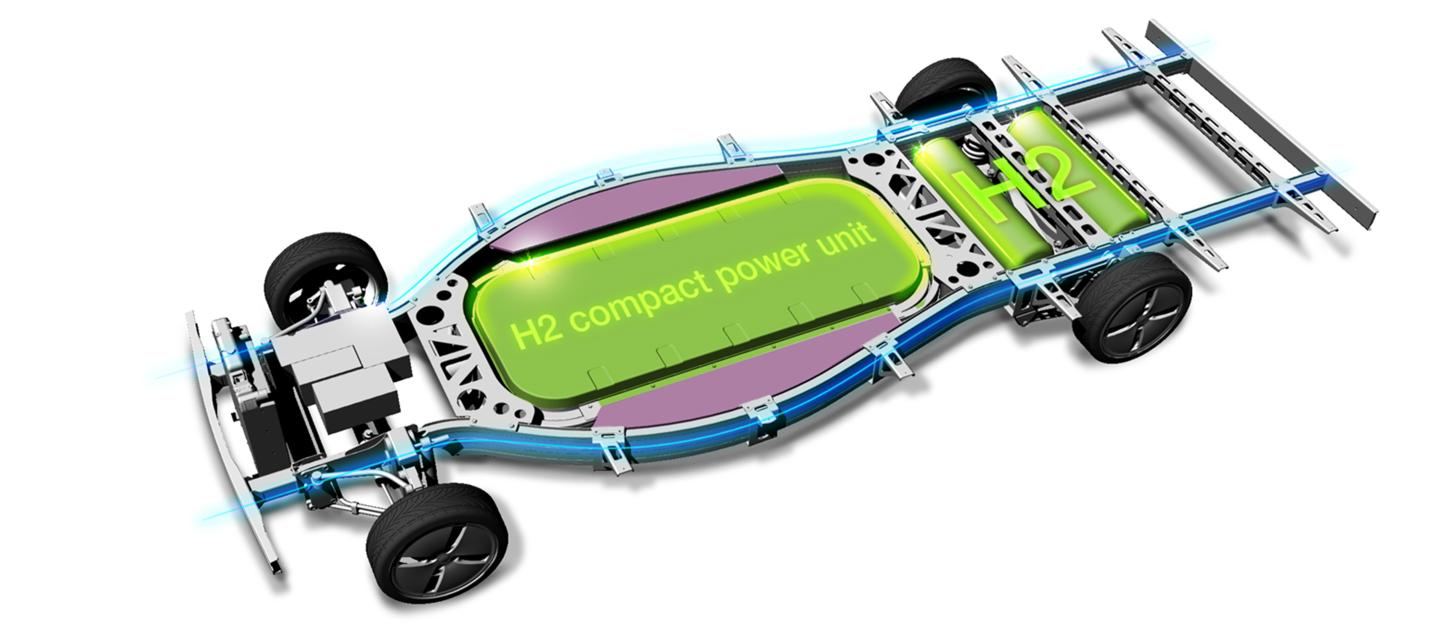

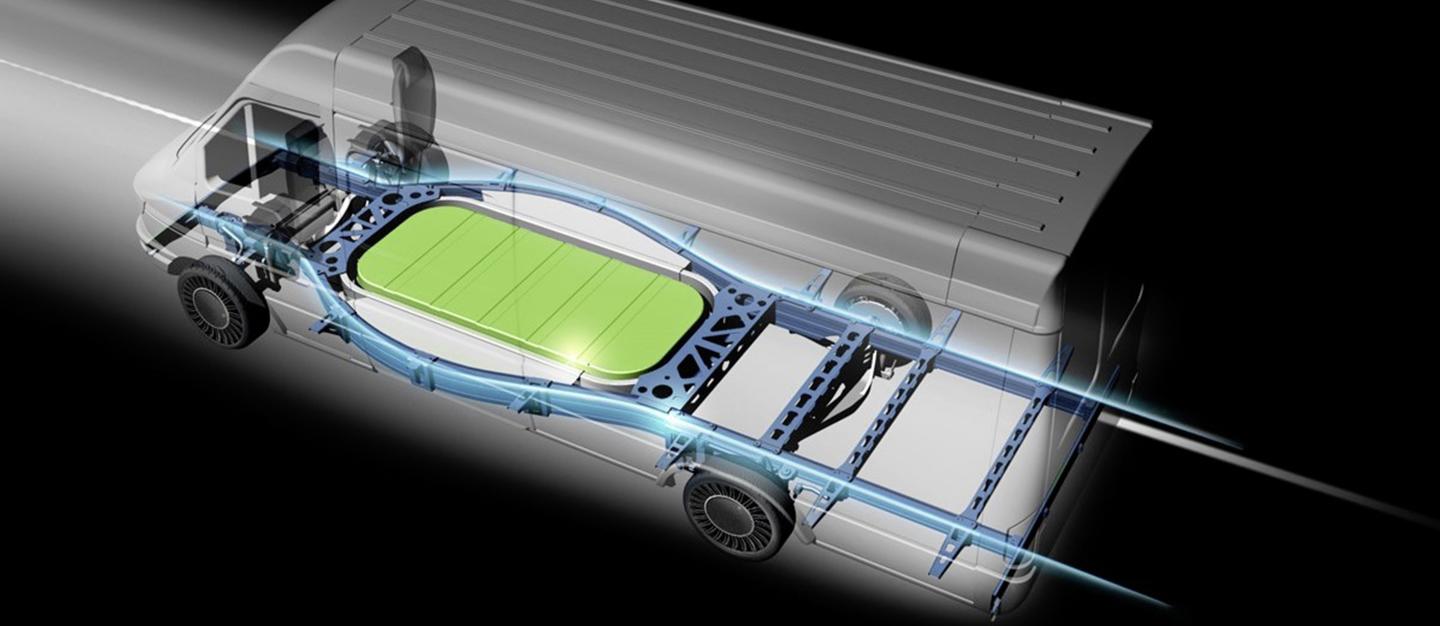

Solutions for future urban mobility and logistics necessitate new, customised systems for alternative drive sources. For this purpose, we have developed a chassis for lightweight electric commercial vehicles.

It is characterised by a bionic lightweight design approach that can be seen both in the topology and in the component design. The non-linear chassis topology facilitates systemic protection of the energy storage units in the chassis and thus reduces the weight and costs for the accommodation and protection of the batteries. The non-linear longitudinal members are made in turn from steel multi-chamber profiles that are designed specifically for the absorption of impact energy in the case of a side crash.

> The HÖRMANN Group with innovative chassis concept at the IAA

The underlying, innovative production technology allows a high number of variants in the profile configuration without additional tooling costs and is thus able to cover a high number of vehicle variants with regard to the wheelbase and battery dimensions.

The vehicle is equipped with wheel hub direct drives and thus has a reduced entrance height and at the same time maximises the potential loading volume of the body.

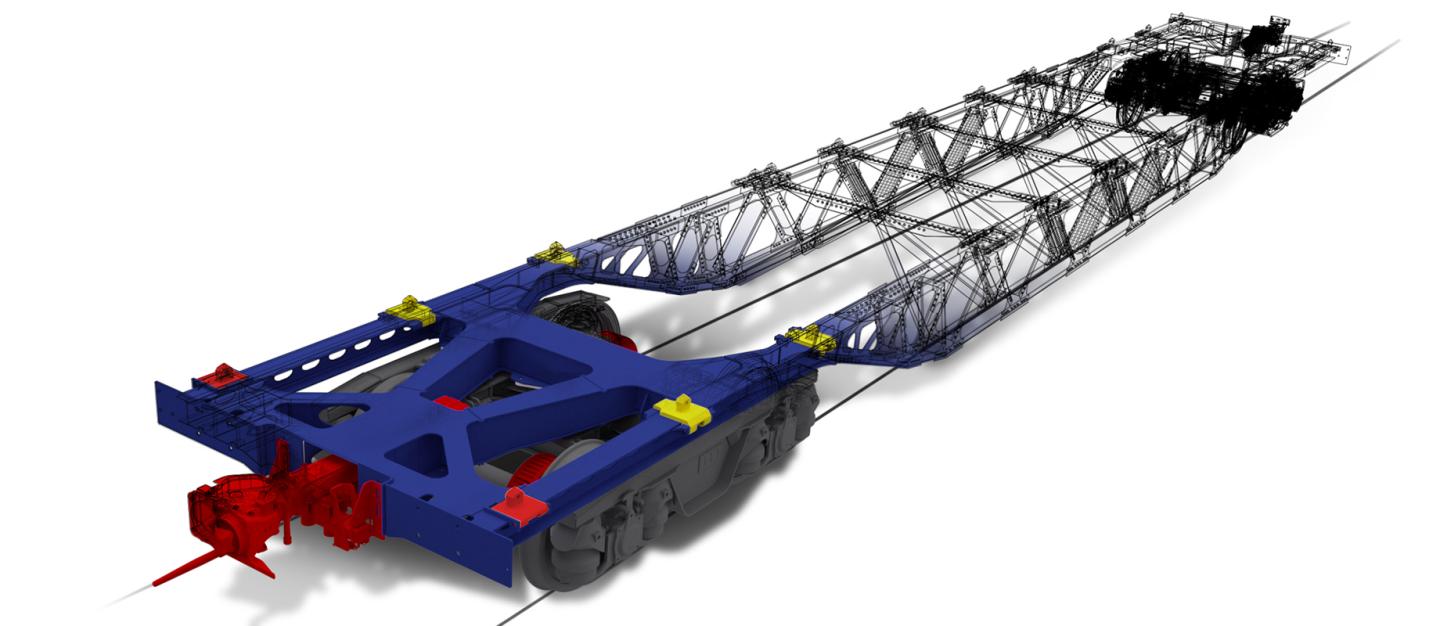

Innovation for railway traffic

HÖRMANN Automotive is also breaking new ground together with HÖRMANN Vehicle Engineering in railway traffic. The development of an innovative wagon underframe for railway freight traffic departs from conventional welded assemblies and is instead based on a mechanically joined lightweight framework structure.

The underframe concept addresses several customer benefits: Due to the use of highly efficient production technologies, the standardized framework elements can be produced in a cost-efficient and short-cycle manner. The subsequent use of mechanical joining methods reduces the production expenditure and component distortion and also offers potential for a reduced assembly time.

At the same time, the wagon structure can be customised in a targeted manner for different lengths and container loads – in terms of both the required lengths and the underlying loads. This results in a significant reduction in the amount of material used, the overall weight and the manufacturing costs.

The associated new standardised end piece concept also allows the use of different coupling systems and bogies in addition to a weight reduction. At the same time, the end pieces can be combined with different centre sections, which allows greater flexibility and an overall cost reduction.

Innovation for semitrailers

A lightweight design for semitrailers allows a higher payload and thus greater transport efficiency. The decisive prerequisite in a highly cost-sensitive market is economic lightweight design strategies. For this purpose, HÖRMANN Automotive has developed lightweight designs that can make a sustainable contribution to weight reduction in semitrailers and represent the basis for the ongoing development towards an ultra-lightweight trailer concept.

The vision here is that the semitrailer as the actual “goods carrier” will become a digitalised core element of future, climate-neutral heavy-duty distribution traffic.

2. Innovation in Technology Development

We support you in the implementation of your ideas with new technological approaches. For this purpose, we are working consistently on the further development of our technologies and processes at the cutting edge of the trends we are currently experiencing in the form of alternative drive systems and digitalisation.

Development of lightweight technologies

The discipline of lightweight design is experiencing a whole new relevance against the background of alternative drives: The objective is to reduce the moving masses in order to increase the range and compensate for the payload lost due to the energy storage units. We are achieving this through the development of new process chains for processing high-performance steel and non-ferrous materials. At the same time, we see great potential in having the requisite technological proficiency for the realisation of load-adaptive structures for lightweight structures. Conventional forming methods often only offer the required degrees of freedom in association with significant additional costs. Due to the increasing flexibility of the forming process with regard to the realisable degrees of freedom for the component parts, we are in the position to produce load-optimised structures and are also able to do so in a cost-efficient manner with a high number of variants. We are currently pursuing this objective in particular with our efforts in relation to free-form bending and linear flow splitting.

Integrally branched structures due to linear flow splitting

The production of integrally branched profiles offers innovative solutions with regard to component part connection and the use of integrally branched multi-chamber profiles. In this connection, a flat sheet is formed into a double T-profile as part of a continuous rolling process by the forming rollers at both strip edges; this double T-profile offers new design options against the background of lightweight design and the integration of functions. At the same time, it is possible to produce non-linear profiles via the integration of a bending process in the production line. As a result, the large-scale production method known as “linear flow splitting” can also offer significant added value in applications with a high number of variants. This has been proven in connection with the bionically oriented vehicle topology of the Hörmann integral chassis, which can be produced with minimal tooling investment via the described process chain even in the case of a high number of variants – in particular with regard to the wheelbase and chassis dimensions.

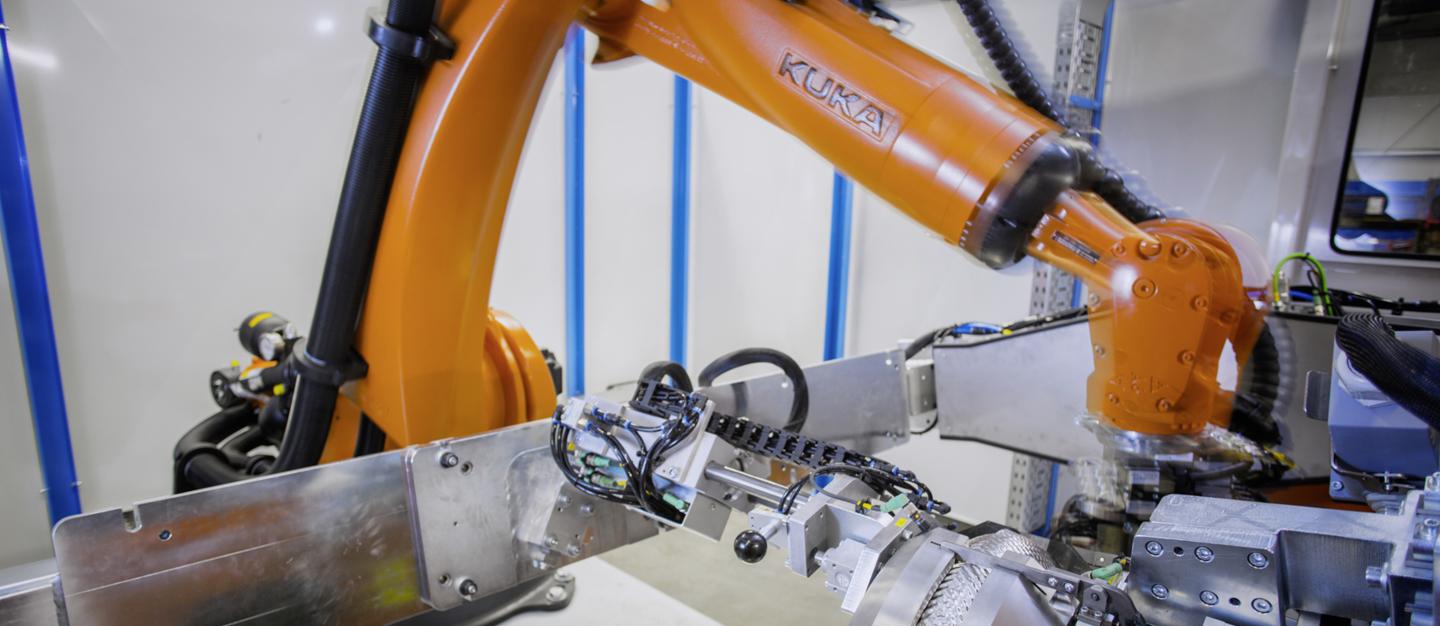

Free-form bending

The stringent continuation of the core technology topic of tube bending at HÖRMANN Automotive is realised by free-form bending. Extensive geometric design freedoms in the profile configuration without additional tooling costs allow the cost-efficient production of innovative, topologically optimised structures. In this connection, we work closely with plant manufacturers and universities in the ecosystem to further develop free-form bending against the background of component part tolerances that have to be adjusted in a batch- and geometry-related manner via adapted control mechanisms.

Forming high-strength aluminium alloys

New developments in aluminium materials are making high strengths available and enabling a significant weight reduction. However, greater strength and reduced formability require temperature-induced production strategies. Our objective in this connection is to integrate new aluminium materials into the existing process chains of component design and transfer these to series production via the development of new process routes and tooling concepts.

Development of process chains for the production of hybrid composites

In many cases, multi-material systems offer added value, in particular in the area of large component part applications in the agricultural machinery sector, which are both weight- and wear-sensitive and must also fulfil additional functions due to the attachment of a wide range of add-on parts. We are taking this trend into account and working on the development of metal-plastic composites with the focus on optimal material use and intelligent process integration options while at the same time complying with the component performance.

Digitalisation in Forming Technology

Smart products

Forming-related component parts currently fulfil mechanical requirements to the greatest possible extent. We want to go beyond this and create additional benefits by means of component intelligence. For this purpose, we are working in an ecosystem with universities and customers by means of which we check the sensor integration within the production-related process chain. An additional benefit can arise here for us by, for example, recording the component behaviour such as the longitudinal member deflection due to the payload or also the component strain of safety-critical chassis parts due to operating loads and learning how to utilise them.

In this way, we can build on the trend of vehicle digitalisation and offer completely new options for product use in connection with predictive maintenance and condition monitoring. We use group-internal synergies with the Funkwerk IoT, which provides the basis for data evaluation and usage via the use of machine learning and AI algorithms.

Smart tools

Via new tool digitalisation approaches, we are monitoring the component quality where it is created: In the tool. For the first time, the integration of sensor elements in tool systems gives us a transparent insight into the forming process and thus allows us to develop technological processes based on tool-internal cause-effect chains.