Company System

Interview with Dr.-Ing. Daniel Holstein, Managing Director of HÖRMANN Automotive

Mr Holstein, what makes HÖRMANN Automotive stand out from the competition?

HÖRMANN Automotive offers the customer a unique and wide range of products and processes. This range extends from low-volume production with many variants up to high-volume production.

We are characterised by demand-based processes – manual production processes as well as highly automated, linked production cells and lines. For example, we produce outer skin parts for large agricultural machinery in small batches and in large batches for light-duty commercial vehicles (LCV).

Our flat hierarchies also facilitate quick decision-making. One example is our shopfloor management meetings at which we jointly discuss adaptation and change processes and then efficiently implement then.

What distinguishes HÖRMANN Automotive from other suppliers?

At HÖRMANN Automotive, we are very close to the customer and are cater to special requests. It is important to us that we fulfil this objective to the maximum. We need agile processes and flexible production for this purpose. We offer this by continuously adapting and further developing ourselves.

Our expertise built up over the last 60 years and the long-standing partnerships are important foundations in this connection. Our customers are mainly well-known OEMs such as MAN, Daimler, BMW or Porsche. We not only want to provide them with the desired products, but also create added value. Providing our customers with good advice already in the development phase is an integral part of our overall service. Ultimately what counts for the customer is the finished product in perfect quality and reliable delivery. A good end product requires a good initial process – that is where we come in.

Furthermore, we are embedded in a strong group. The HÖRMANN Group is a stable structure and gives us the freedom to plan in the long term and benefit from synergy effects. One successful example of many is our 5L chassis, which we developed together with HÖRMANN Vehicle Engineering on behalf of SBB Cargo.

What is the vision of HÖRMANN Automotive?

Our vision is quite clear: We want to be one of the leading suppliers of metallic components, modules and systems for the European commercial vehicle, agricultural machinery and automotive industries from the product idea up to installation. Our objective is to act as a manufacturer-independent system supplier with a fully functionally group of companies and development competence as well as our own production locations – on a global level.

And what are you already doing en route to this objective?

We offer sophisticated products at high quality and competitive prices thanks to continuous improvements in development, production and logistics. To further expand this position, we need to develop even more intensively in efficient technologies and also optimise the manufacturing footprint internationally. This is the only way that we can offer customers innovative, economic and sustainable solutions.

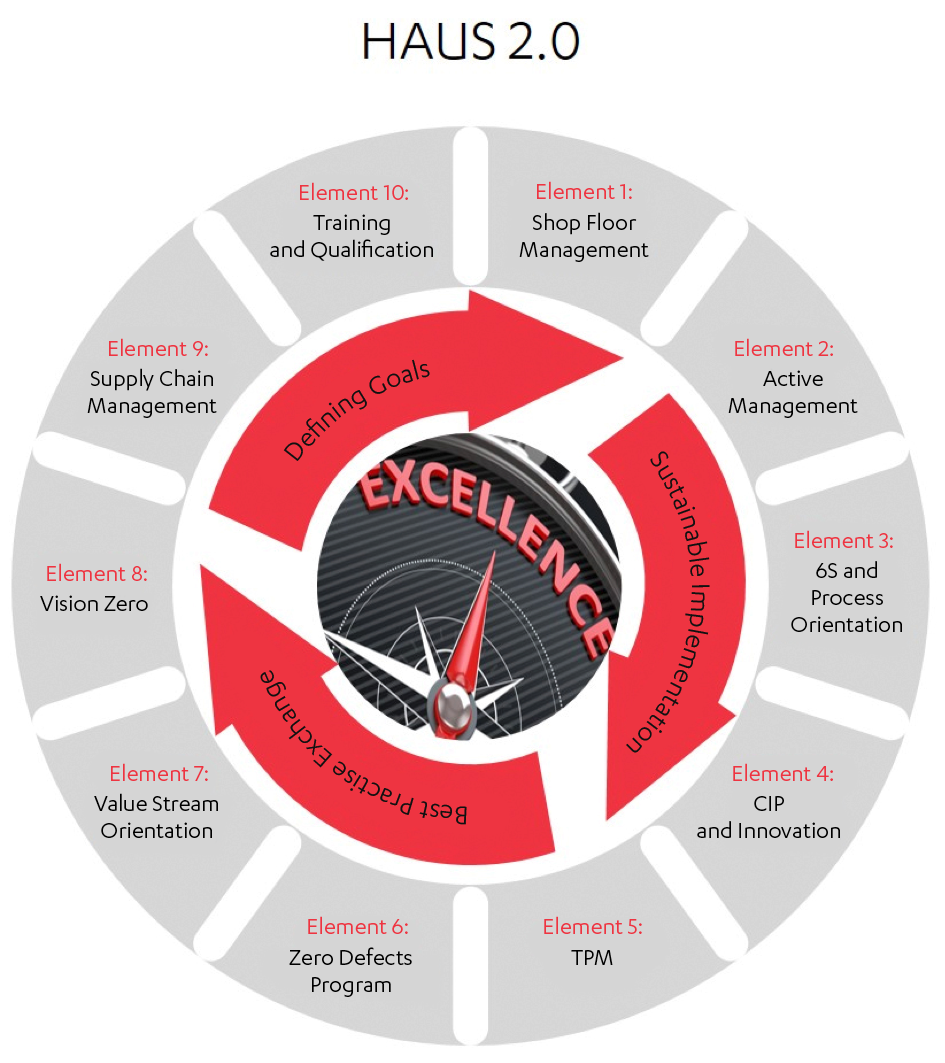

For support, we have set up a company system with the name “HAUS 2.0”, which increases productivity and achieves greater competitiveness and profitability. “HAUS” stands for “Hörmann Automotive Unternehmens System” (Hörmann Automotive Enterprise System). All going by the motto: Operational excellence. The model is based on methods and processes that are optimally connected with each other. This creates a uniform and standardised system that can be implemented in an individual and customised manner.

Let’s take a look at the diagram – what are the basic aspects in HAUS 2.0?

The diagram shows three different rings. The outer ring lists all the required processes required to reach the centre. For this purpose, we have defined 10 elements with corresponding categories. The centre circle symbolises the methodical quality feedback loop – from policy development to sustainable implementation and continuous expansion to best-practice exchange and this both internally and externally. A superordinate process describes the benchmark level. Every year, all the companies in the HÖRMANN Group define their targets for the coming 12 months. The maturity level determination is carried out once a year. All in all, we at HÖRMANN Automotive are always committed to continually optimising ourselves and also practising what we preach in terms of the value “innovative spirit”. HAUS 2.0 creates the framework for this.