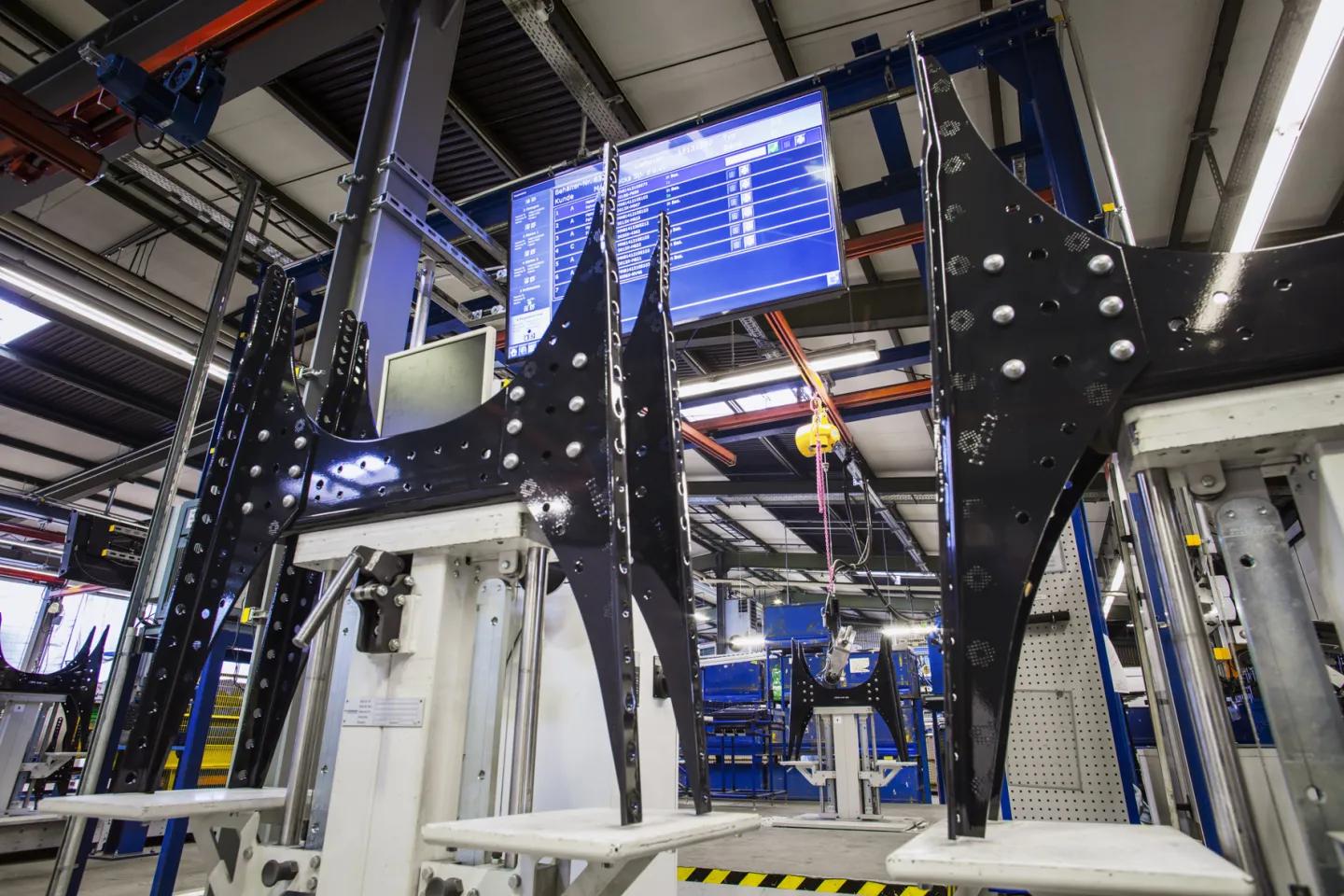

Welded Components

We mainly produce axle-supporting chassis parts with differing degrees of complexity that we deliver directly – in welded assembly and welded component form – to the assembly line. All established robot and manual welding methods (MIG, MAG, TIG) are used and adapted to the material to be welded and customer requirements. Our state-of-the-art facilities guarantee that the customer is provided in each case with the optimal method for a high throughput rate with maximum quality and the lowest possible production costs.

Our range of services covers the following:

- Production of components and replacement parts in low-volume production

- Use of all established robot and manual welding methods (MIG, MAG or TIG)

- Assembly

- Machining

- Just-in-time or just-in-sequence delivery

- Weld-seam test

- Traceability

- Anti-corrosion coating in accordance with customer specification (e.g. cathodic dip painting)

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.

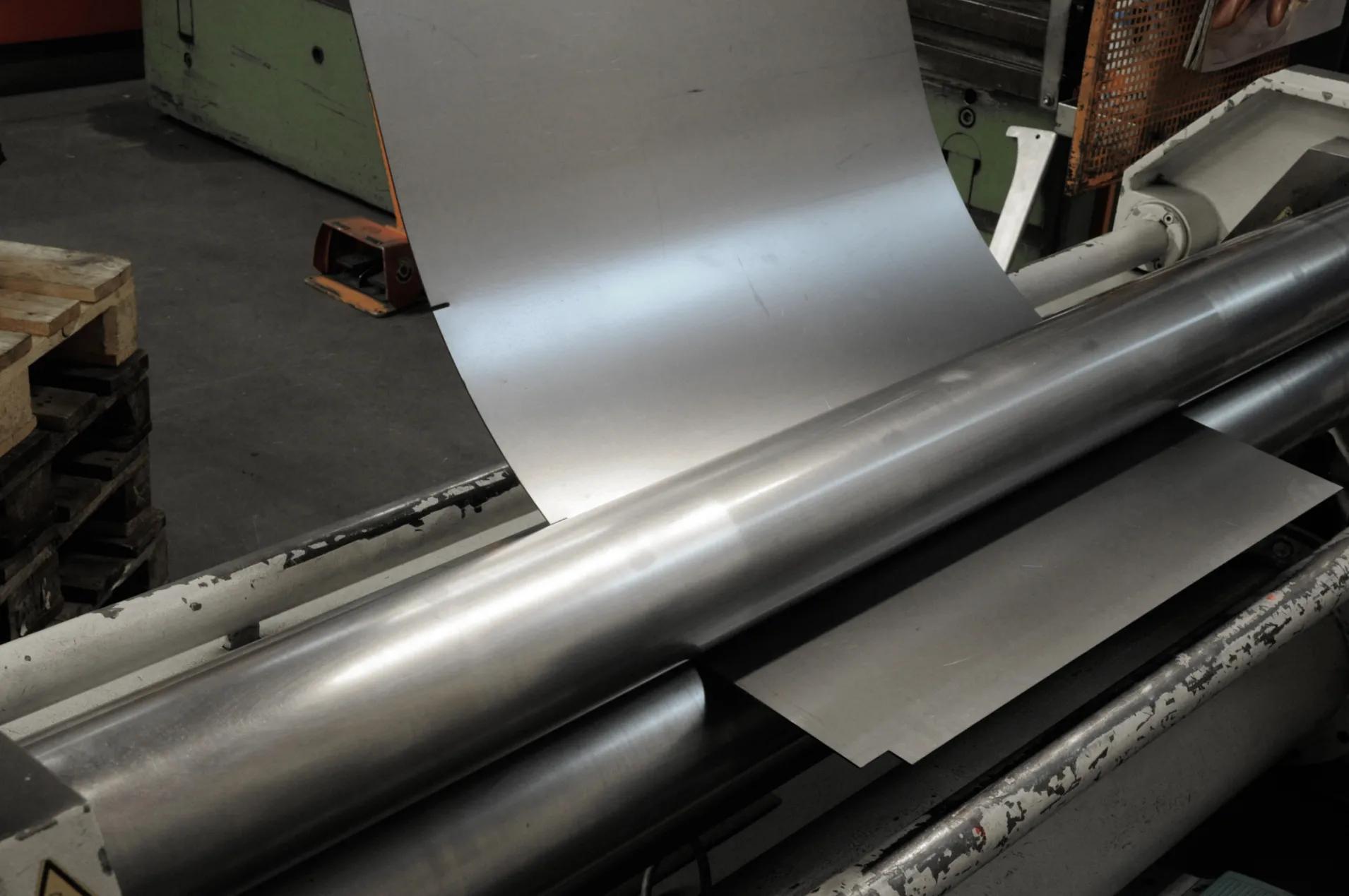

Pressed Parts

We design products for very special requirements to suit the needs of our customers, who primarily come from agricultural and construction machinery technology. In the case of low to average unit figures, low tooling and process costs play an important role: Our employees have the required expertise to solve the conflict between tool and part prices so that the best possible result is achieved for our customers. Besides the usual bare or galvanised deep drawing steels, we are also experts when it comes to stainless steels, copper and aluminium. Sheet thicknesses of between 0.5 mm and 3 mm are formed as what are known as fine sheets. The wings for tractors and side trim parts for harvesting machines and tractors are given here as examples. However, we can also form thick plates of up to max. 8 mm, such as pedal levers, feed hoppers for harvesting machines and shields for exhaust systems. Presses with a pressing force of up to 16,000 kN are available for these tasks.

Our range of services covers the following:

- Development and planning

- Prototyping

- Pressing and forming of deep drawing steel, stainless steel, copper and aluminium

- Fine sheet: Sheet thicknesses of 0.5-3 mm

- Thick plate: Sheet thicknesses of max. 8 mm

- Pressing with a pressing force of up to 16,000 kN

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in St. Wendel here.

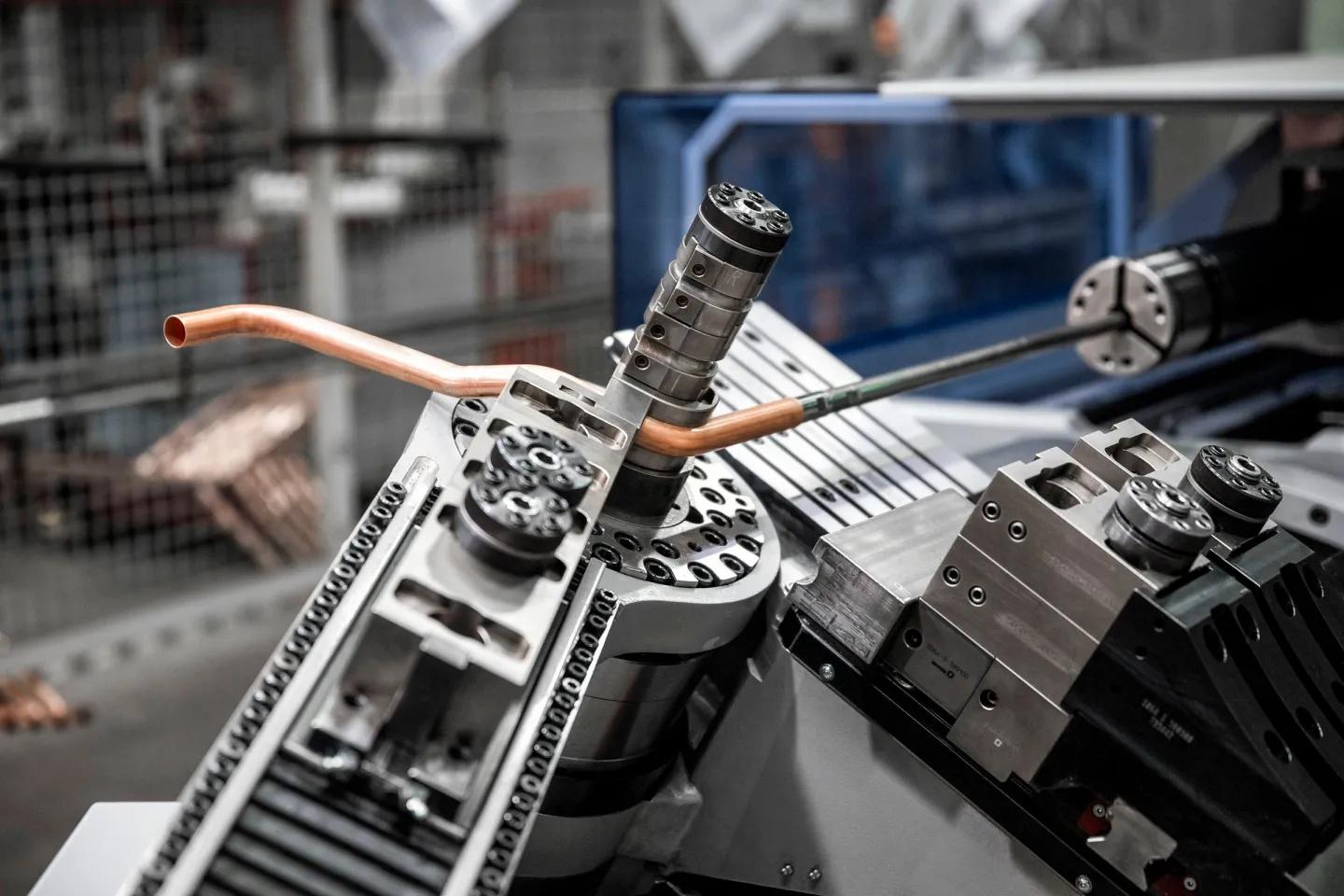

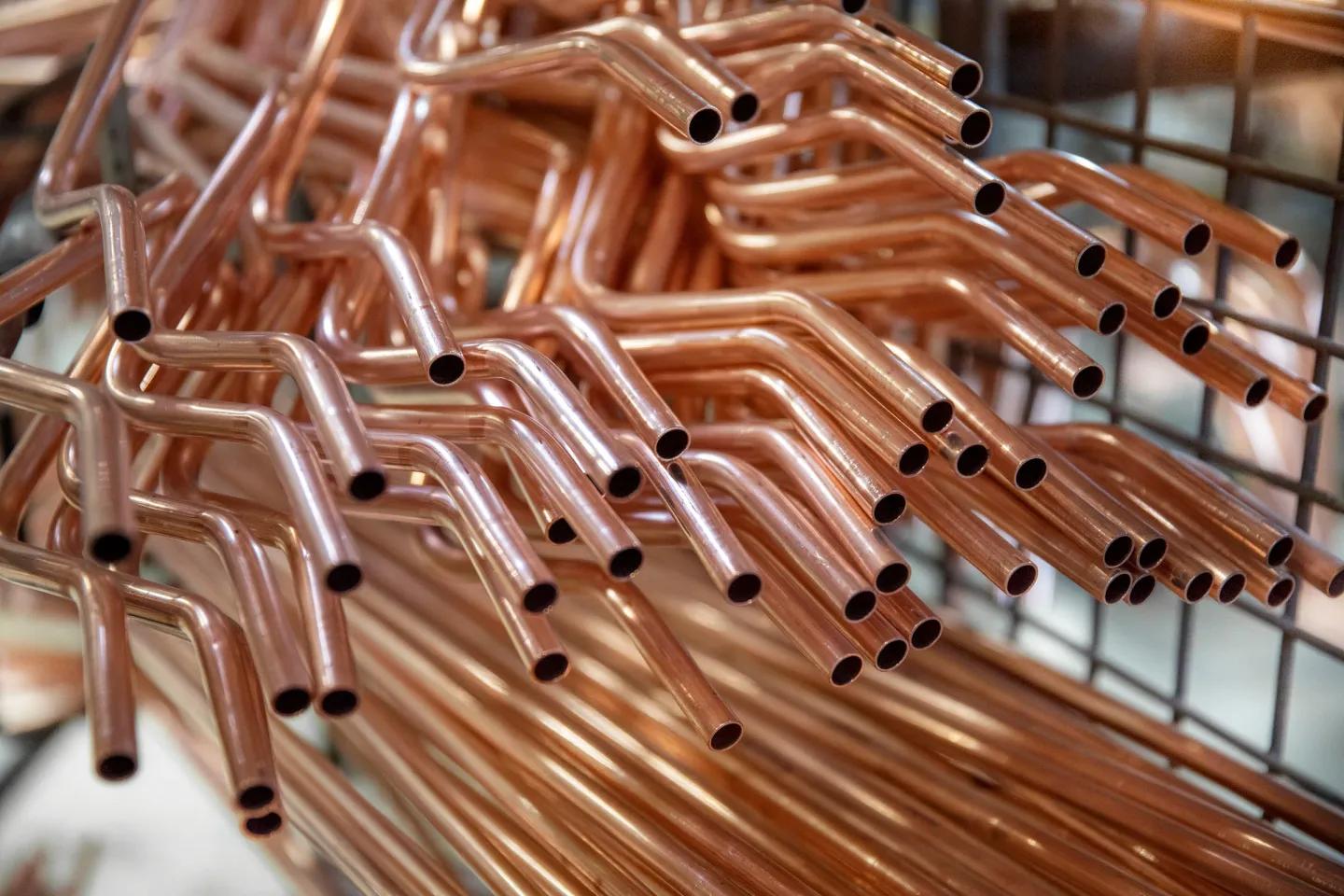

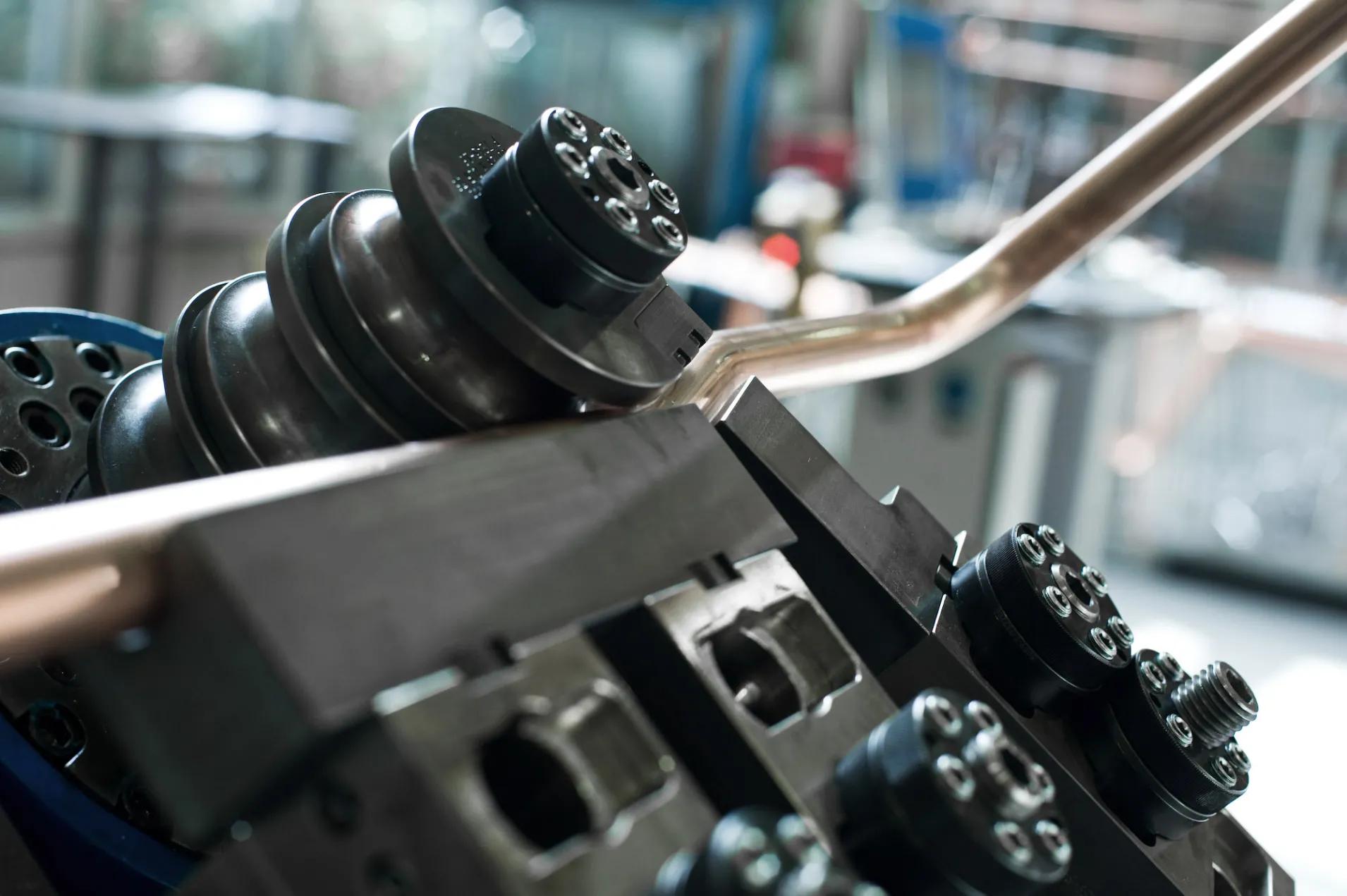

Fuel and Refrigerant Pipes

We have decades of production expertise in the manufacturing of ready-to-install pipe systems for the transport of fuels and refrigerants in buses and passenger cars. In the meantime, we have delivered tens of thousands of complete pipe systems to OEMs. Depending on customer requirements, we form pipes made from steel, stainless steel, copper, brass or aluminium on state-of-the-art CNC bending machines and provide the pipe ends with suitable and stable connections. Besides refrigerant and fuel lines, we can in this way also produce various other line types – for example, hydraulic lines, oil lines or coolant lines. With individually agreed logistics concepts, we contribute to a smooth production process at the customer.

Our range of services covers the following:

- Pipe bending with diameters of between 2 mm and 70 mm to suit the specified bending radius

- Bending of steel, stainless steel, copper, brass and aluminium pipes

- Attachment of connections by means of induction soldering and brazing

- Pipe end processing in accordance with the customer drawing

- Initial sampling of new lines

- Vehicle-related delivery (one-set flow), just-in-time or just-in-sequence

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.

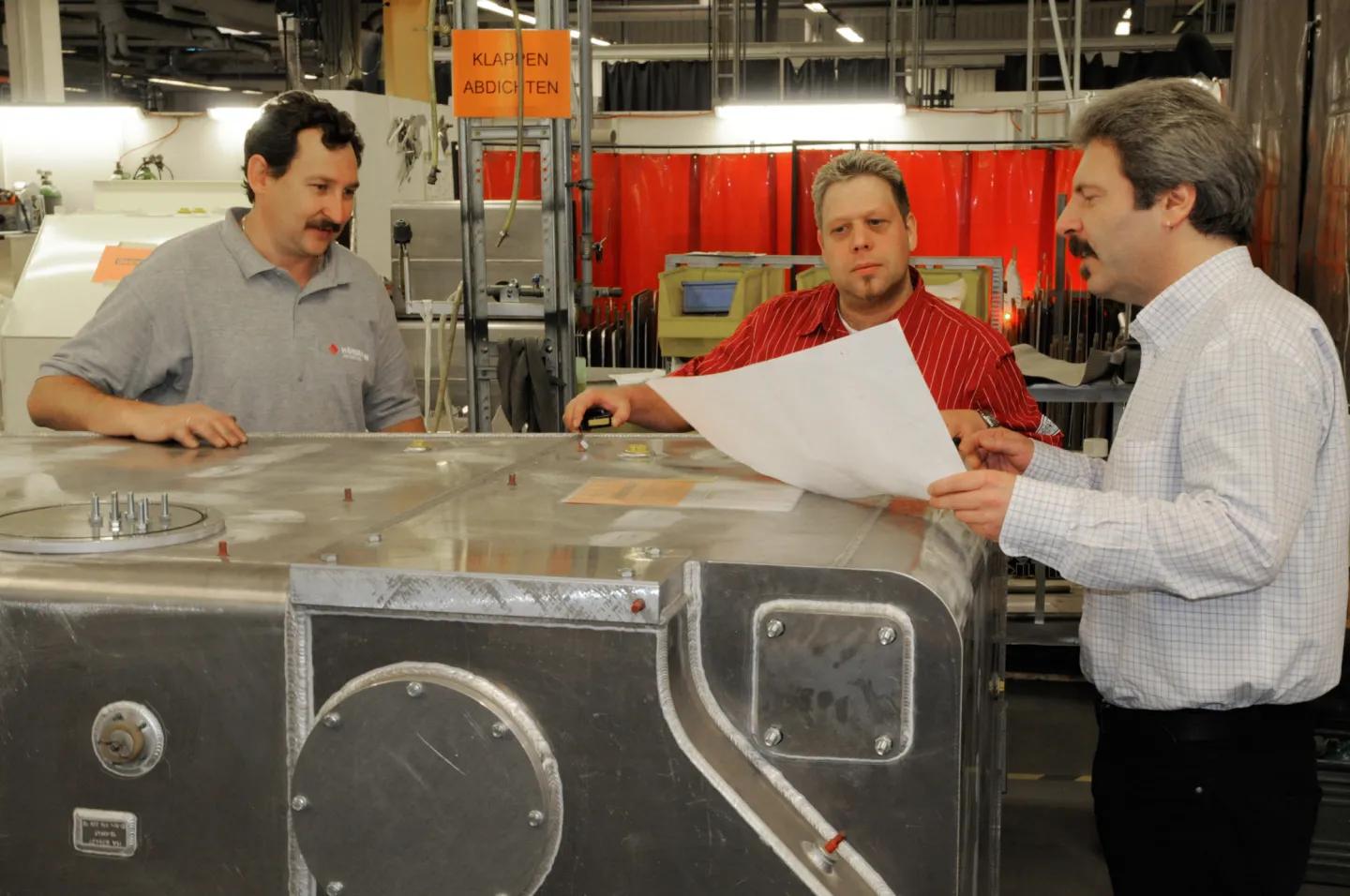

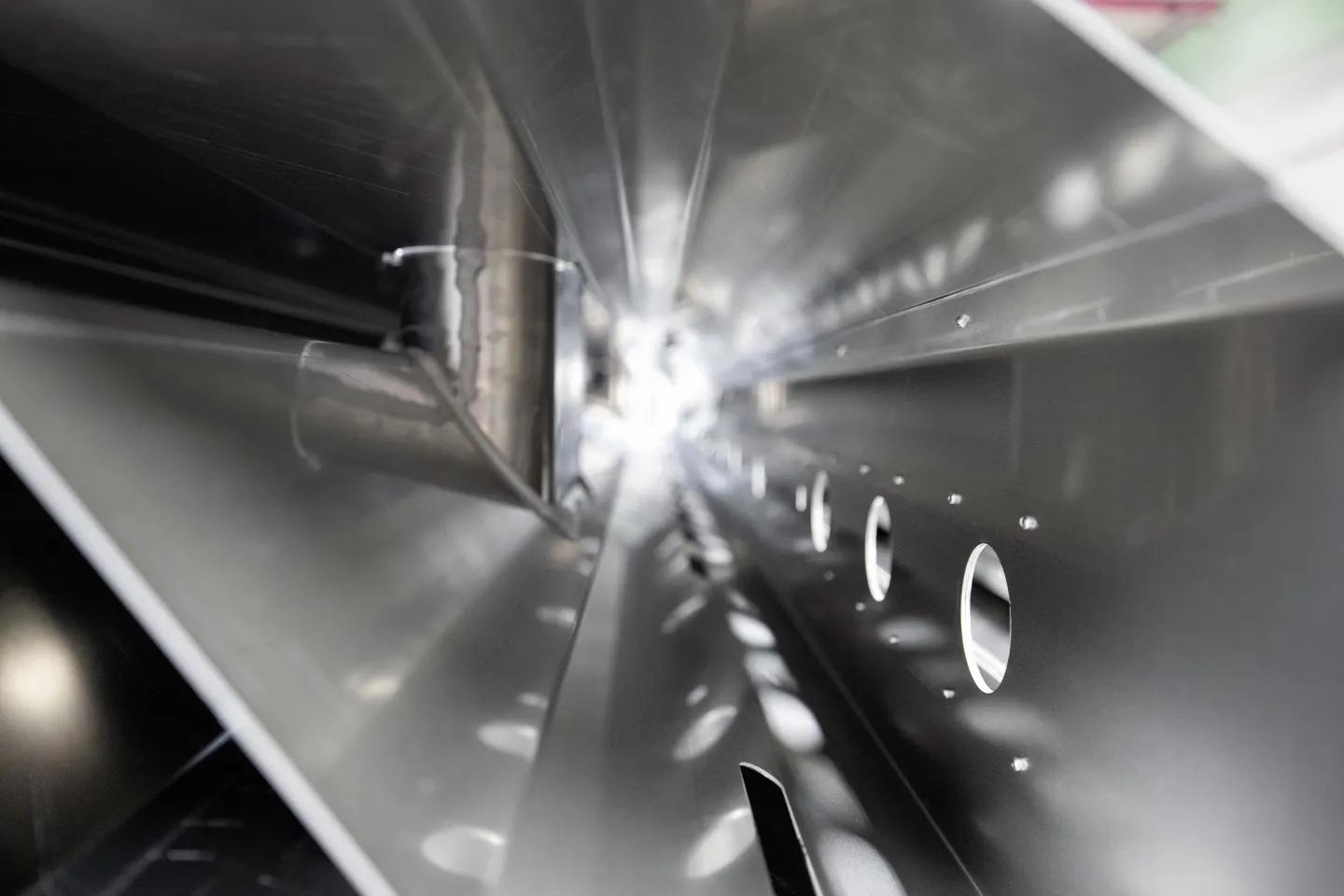

Fuel and Hydraulic Tanks

We have decades of experience in the production of fuel and hydraulic tanks. In this connection, the customer specifies, for example, the connection points and we engineer the tank to suit the available installation space, then we produce prototypes that we subsequently bring to series production maturity in coordination with the customer – taking into account technical simplification with the objective of cost optimisation. We make the tanks from steel, stainless steel and – something that is becoming increasingly important nowadays – aluminium. The capacity of our tanks ranges from 0.25 l to 2,200 l. Our logistics concepts, which we individually coordinate with the customer, play a key role in a smooth process along the entire value-added chain.

Our range of services covers the following:

- Programming and blanking

- Forming (edging, pressing, rounding)

- Longitudinal seam, robot and manual welding (MIG, MAG, TIG)

- Cleaning and leak tests

- Powder coating and final assembly

- Quality control and proper packaging

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Eislingen here.

Bus Ceiling Systems

We are specialised in the production and ready-to-install assembly of interior equipment systems for commercial vehicles, in particular of ceiling systems. The ceiling systems in city buses and coaches are nowadays much more than decorative panels. These now conceal a complex structure of subsystems in a confined installation space that ensure greater safety and comfort for passengers: Functions such as cooling/air conditioning, audio and lighting must be optimally integrated in the confined installation space available. The objective here is functional reliability as well as weight reduction and ease of maintenance. We offer a comprehensive range of services for roof internal systems to suit customer requests. From the design to the development of prototypes to engineering, series production and delivery.

Our range of services covers the following:

- Engineering and series production from a single source

- Just-in-sequence delivery

- Supplier selection with regard to expertise, delivery reliability and quality

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Saarbrücken here.

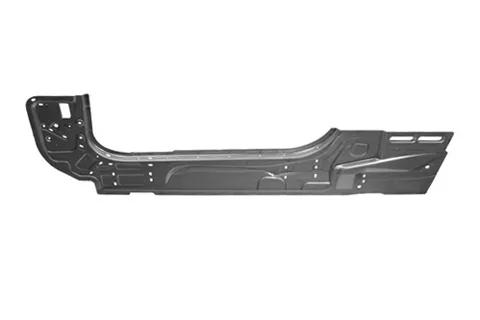

Chassis

We offer our customers the following for the “chassis” area:

- Vehicle chassis parts (e.g. longitudinal frame members), also as complete, ready-to-install units with a sheet thickness of up to 12 mm

- Detachable body components and chassis parts such as crossmembers, gusset plates, reinforcements with a sheet thickness of up to 12 mm

- Surface technologies such as zinc-phosphate coating, cathodic dip painting (CDP) and topcoat systems

- Planning, design and manufacturing of production-specific cutting, bending and drawing tools

- Frame pre-assembly, just-in-sequence and module deliveries

Into quality in a big way

We produce all kinds of detachable body components and chassis parts made from sheets up to 12 mm thick and in material grades up to QStE 700 TM. The range of parts encompasses crossmembers, detachable parts, gusset plates, reinforcements and welded body components for truck frames. We have particular expertise in the joining of pressed parts to form components. In addition to CDP priming, the option exists to use an additional topcoat.

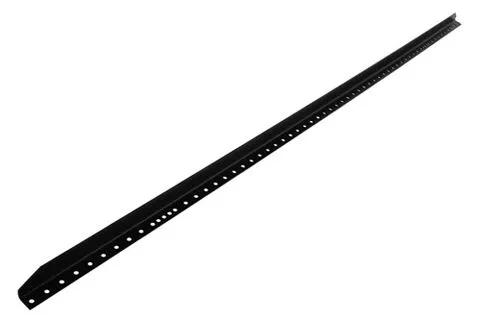

Product group: Longitudinal frame members

For light-, medium- and heavy-duty truck model series, we produce longitudinal frame members made from high-strength materials up to QStE 500 TM and in material thicknesses of up to 10 mm. Longitudinal frame members are available in straight and bent designs and with individual hole patterns. Two large presses with a pressing force of up to 50,000 kN as well as a roll-forming system for rolling the longitudinal members are available for production. The state-of the-art cathodic dip painting system is designed for maximum corrosion protection with zinc-phosphate coating via spraying and cathodic dip painting.

Product group: Detachable frame components

For light-, medium- and heavy-duty truck model series, we produce detachable frame components made from high-strength materials up to QStE 700 TM and in material thicknesses of up to 12 mm. Four press lines, production cells for assemblies and a cathodic dip painting system with pretreatment and cataphoretic immersion priming are available at two locations for production.

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Gustavsburg here.

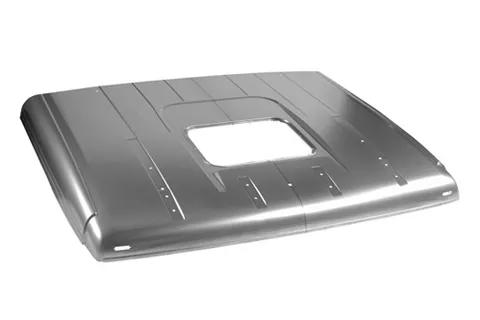

Body-In-White

Product group: Outer skin Product group: Structural parts Product group: Assemblies

We deliver everything required to form the outer body skin of a vehicle. Our production portfolio includes body parts for passenger cars as well as cab and trim parts for trucks. We are a competent partner not just as a part producer, but also as a supplier of modules, assemblies and ready-to-install system components. Fine sheets up to 3 mm thick are processed in accordance with EN 10143 and EN 10131. Production takes place on fully automated press lines and in flexible production cells with state-of-the-art laser systems and welding and bonding robots. Our aspiration: Top quality. For example, as a supplier for outer skin parts we fulfil the exacting demands of European passenger car manufacturers.

Our range of services covers the following:

- Outer skin and structural parts up to 3.0 mm thick

- Bonding and welding technology

- Surface technologies such as zinc-phosphate coating, cathodic dip painting (CDP) and topcoat systems

- Planning, design and manufacturing of production-specific cutting, bending and drawing tools

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Gustavsburg here

Aluminium Panels and Flaps

In addition to tanks, the production of luggage compartment and fuel filler flaps as well as panels made from aluminium for buses and commercial vehicles is another of our core competencies. For example, all Setra coaches delivered in the last 20 years are equipped with our flaps and today we look after the replacement parts business for these. We deliver ready-to-install flap systems made from aluminium in accordance with customer requirements. It goes without saying that we develop flap concepts together with our customers taking into the account the functionality and weight optimisation.

Our range of services covers the following:

- Programming and blanking

- Milling and forming (rounding, edging, rolling in)

- Alignment and grinding

- Pretreatment and powder coating

- Adhesive bonding, sealing and assembly

- Quality control and proper packaging

Are you interested in this product?

You can find the contact details for HÖRMANN Automotive in Eislingen here.

Certifications

With a comprehensive level of service, we deliver the components and systems just-in-time or just-in-sequence – upon request also in a vehicle-related manner (one-set flow) – directly to the assembly line of our customers.

Our production system is geared towards the usual high number of variants and batch size of one associated with commercial vehicles together with the restriction of short throughput times and a desired delivery performance of 100%. In this connection, we constantly monitor the entire supply chain by means of our ERP system in order to have the required direct material available at the required point in time.

Our range of services covers the following:

- Individually coordinated logistics concepts

- Just-in-time or just-in-sequence deliveries

- Vehicle-related deliveries (one-set flow)

- Deliveries starting at a quantity of 1+x

- Customs declaration and clearing

HÖRMANN Automotive supports value-based transparency and performance as well as a structured way of working so that we can focus on the requirements of the automotive and commercial vehicle industries with the highest quality standards while complying with the occupational safety and environmental management systems.

We see change as an opportunity!

We take a proactive approach to the demands placed on our business model by changing markets, volatile customer requirements, numerous product changes, complex, multi-variant customer products and climate change. We respond to changes promptly and continuously optimise our processes to achieve new target states.

Decoupled shifts with demand-orientated shift ends and quality-conscious, well-trained and flexible employees ensure that the product quantity required by the customer is always guaranteed to be available on the delivery date. All our processes are equipped with the necessary emergency concepts to ensure that we are able to deliver at all times. The same applies to our IT systems. Customer call-offs are received via our SAP system and forwarded to all suppliers accordingly.

Social responsibility

In order to fulfil our social responsibility, we are committed to protecting the environment in the sense of the circular economy, from the selection of resources to the recycling-friendly product concept. We communicate this to our partners. It is also our aim to make our employees' workplaces safe and liveable by minimising the use of hazardous substances and reducing risks, and to maintain them in the long term.

For all products and services, working in accordance with various quality standards ensures globally recognised and certified, sustainable quality and reliability, which is checked and guaranteed through regular inspections and audits as well as continuous further development. In this way, we continuously create added value for our customers.

Our environmental management system is certified according to various standards. We strive for continuous improvement and further development. The environmental management system is continuously re-evaluated and we are always on the lookout for new ways to further conserve resources and the environment.

In line with our company quality, occupational health and safety management, we actively approach our employees and involve them in our decision-making. We take our social responsibility as a company very seriously. This is why sustainability and environmental protection play an important role in our corporate philosophy. Consequently, we use energy and resources responsibly and efficiently.

Certificates HÖRMANN Automotive Banovce

Certificates HÖRMANN Automotive Gustavsburg

ISO 14001:2015

ISO 50001:2018

IATF 16949:2016

DIN EN ISO 3834-2:2021

TISAX® Assessment Scope S71K15

Sustainability Rating

Certificates HÖRMANN Automotive Saarbrücken

ISO 9001:2015

IATF 16949:2016

Certificates HÖRMANN Automotive St. Wendel

IATF 16949:2016

Certificates HÖRMANN Automotive Wackersdorf

IATF 16949:2016

Certificates

With a comprehensive level of service, we deliver the components and systems just-in-time or just-in-sequence – upon request also in a vehicle-related manner (one-set flow) – directly to the assembly line of our customers.

Our production system is geared towards the usual high number of variants and batch size of one associated with commercial vehicles together with the restriction of short throughput times and a desired delivery performance of 100%. In this connection, we constantly monitor the entire supply chain by means of our ERP system in order to have the required direct material available at the required point in time.

Our range of services covers the following:

- Individually coordinated logistics concepts

- Just-in-time or just-in-sequence deliveries

- Vehicle-related deliveries (one-set flow)

- Deliveries starting at a quantity of 1+x

- Customs declaration and clearing

HÖRMANN Automotive supports value-based transparency and performance as well as a structured way of working so that we can focus on the requirements of the automotive and commercial vehicle industries with the highest quality standards while complying with the occupational safety and environmental management systems.

We see change as an opportunity! We are pro-actively tackling the requirements being placed on our business model by changing markets, volatile customer requirements, numerous product changes, complex customer products with numerous variants as well as climate change. We face up to the changes promptly and continuously optimise our processes to achieve new target states.

Due to decoupled shifts with a demand-oriented end of shift as well as quality-conscious, well-trained and flexibly deployable employees, it can always be ensured that the product quantities demanded by the customer are available as per the delivery date. All our processes have the required contingency plans in order to be in the position to deliver at all times. This equally applies to our IT systems. Customer release orders are received via our SAP system and accordingly forwarded to all suppliers.

To fulfil our social responsibility, we undertake to protect the environment through a circular economy, starting with the selection of the resources up to a recycling-compatible product concept. We also communicate this onto our partners. It is similarly our goal to design the workplaces of our employees so that they are safe and attractive via the minimal use of hazardous materials and reduced exposure to hazards and to safeguard them in the long term.

For all products and services, the work to various different quality standards ensures a globally recognised and certified as well as sustainable quality and reliability that is checked and guaranteed via regular shopfloor visits and audits as well as constant further development. In this way, we continuously create added value for our customers.

Our environmental management system is certified to various different standards. We strive for continuous improvement and further development. The environmental management system is continuously re-evaluated and we are always on the lookout for new ways to further conserve resources and protect the environment.

In accordance with the operational quality, occupational safety and health management systems, we actively approach our employees and involve them in our decision-making. We take our social responsibility as a company very seriously. This is why sustainability and the protection of the environment play an important role in our corporate philosophy. As a result, we use energy and resources in a responsible and efficient manner.

Leitlinien

IATF 16949:2016

IATF 16949:2016

IATF 16949:2016

IATF 16949:2016

ISO 14001:2015

ISO 9001:2015

ISO 9001:2015

ISO 9001:2015

ISO 14001:2015

ISO 14001:2015

ISO 50001:2011

ISO 50001:2011

DIN V 4113-3:2011