HÖRMANN Automotive – Part of the HÖRMANN Group

HÖRMANN Automotive GmbH consists of six high-performing companies with decades of experience in the development, production, assembly and logistics of components for the automotive industry.

Our plants are specialised in small-, medium-, and large-volume metal components as well as individual one-off products. With our core competencies, we aim to meet the daily needs of the commercial vehicle, agricultural machinery, construction, automotive and automotive supplier industries.

Strategic Business Segments

The business of HÖRMANN Automotive can be divided into three strategic business segments: Truck, Off-Road and E-Mobility.

- In the “Truck” business segment, we are specialised in the production of frame and BiW components for commercial vehicles. Particularly with regard to the commercial-vehicle frame, we cover a holistic technology portfolio with the production of longitudinal frame members, detachable frame components, welded assemblies and pipes and are available to our customers as a system partner. Due to our extensive technological expertise, we already provide our customers with valuable input and advice on cost-efficient and innovative component design at an early stage of the product creation process.

- The “Off-Road” business segment gives us wide-ranging access to customers thanks to a broad technology portfolio. We are specialised in flap systems for agricultural machinery and buses, tank systems for agricultural and construction machinery as well as complex welded assemblies for off-road requirements. Here, too, we support our customers in the area of product creation as an active development partner thanks to our extensive expertise in this technology.

- Future mobility is being influenced in a lasting manner by electrification; this will allow new solutions in many of our customer sectors. We are responding to these requirements and potential with the aspiration to actively shape future mobility, e.g. via the assembly of charging stations or components for electric vehicles. In the “E-Mobility” business segment, we thus feel obliged to develop and deliver innovative system solutions in line with demand and consistently orientate our actions – including in the “Truck” and “Off-Road” areas – to this obligation.

The successful growth course enjoyed by HÖRMANN Automotive is thanks to its committed and highly qualified employees, the unique technological position in our business segments and over 50 years of experience in the global automotive market. Every single component constructor at HÖRMANN Automotive is part of a coordinated production system – thanks to the intensive exchange of knowledge, accelerated development processes in ecosystems and digital networking in the HÖRMANN Group. Furthermore, we shape future mobility with our customers and together accompany new products every step of the way to market maturity.

HÖRMANN Automotive develops and constructs the components for a whole.

Management

Managing Director

Christian Petters

Managing Director

Dr. Jürgen Lechler

HÖRMANN Automotive GmbH is Part of the HÖRMANN Group

HÖRMANN Automotive GmbH is part of a strong group – the HÖRMANN Group. The HÖRMANN Group has grown steadily since its formation in 1955. HÖRMANN Holding GmbH & Co. KG is the parent company of 30 subsidiaries operating in the Automotive, Communication, Engineering and Services segments with a high degree of entrepreneurial initiative and independence.

The objective of the HÖRMANN Group is to provide customers with economic, innovative and sustainable solutions and services that offer them significant advantages and clear benefits. The Group, which has approximately 3,000 highly qualified employees, uses the entire scope of its widely diversified and networked knowledge from the extremely diverse technological areas to achieve this goal.

Due to the range of diversified, highly qualified technologies and services, the Group aims to make itself independent of economic influences and to thus minimise the risk for the companies and their employees.

Thinking and acting in this way creates the space to develop perfect customer solutions using our vision, motivation and passion. A concept that is impressively confirmed by the success and continuous growth experienced by the HÖRMANN Group.

HÖRMANN Automotive is Part of a Strong Group of 27 Affiliated Companies

The companies of the HÖRMANN Group are always situated in the best possible strategical and logistical locations for our customers.

The company locations of the HÖRMANN Group in Germany are shown on the interactive map.

HÖRMANN Automotive Gustavsburg GmbH

HÖRMANN Automotive Gustavsburg GmbH is specialised in the production of high-quality chassis, body and add-on parts for the highly competitive commercial vehicle and automotive industries. All this is embedded in a complete process chain with a mature logistics concept – from the idea to the finished system.

Chassis, body and add-on parts for the commercial vehicle and automotive industries

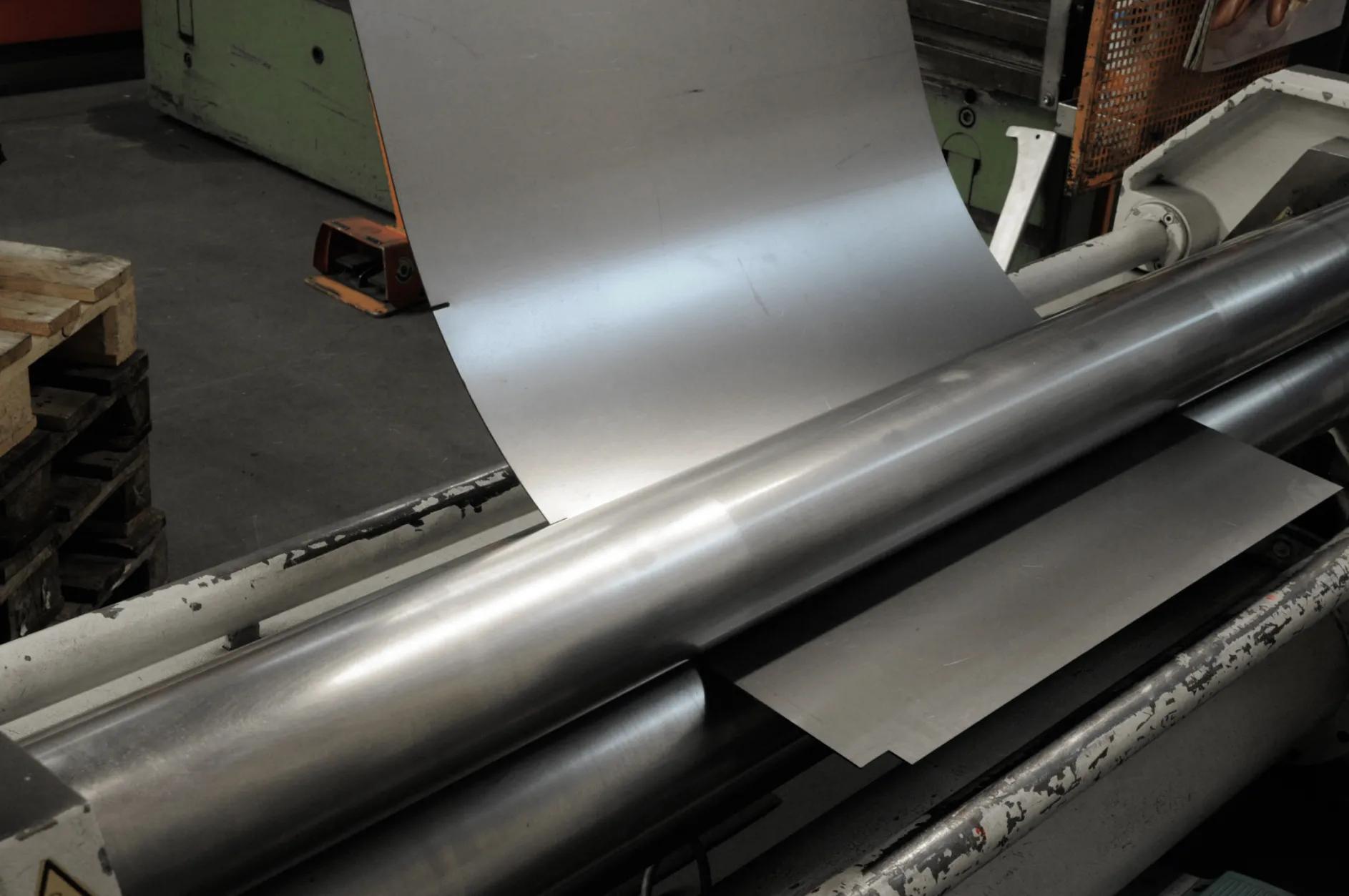

Innovative technology and state-of-the-art solutions in forming, welding and automation technology as well as processes involving coil lines, press lines for up to 5,000 tonnes and laser centres for high-strength steels up to 12 millimetres make vehicles components “Made in Gustavsburg” top-quality products in their field.

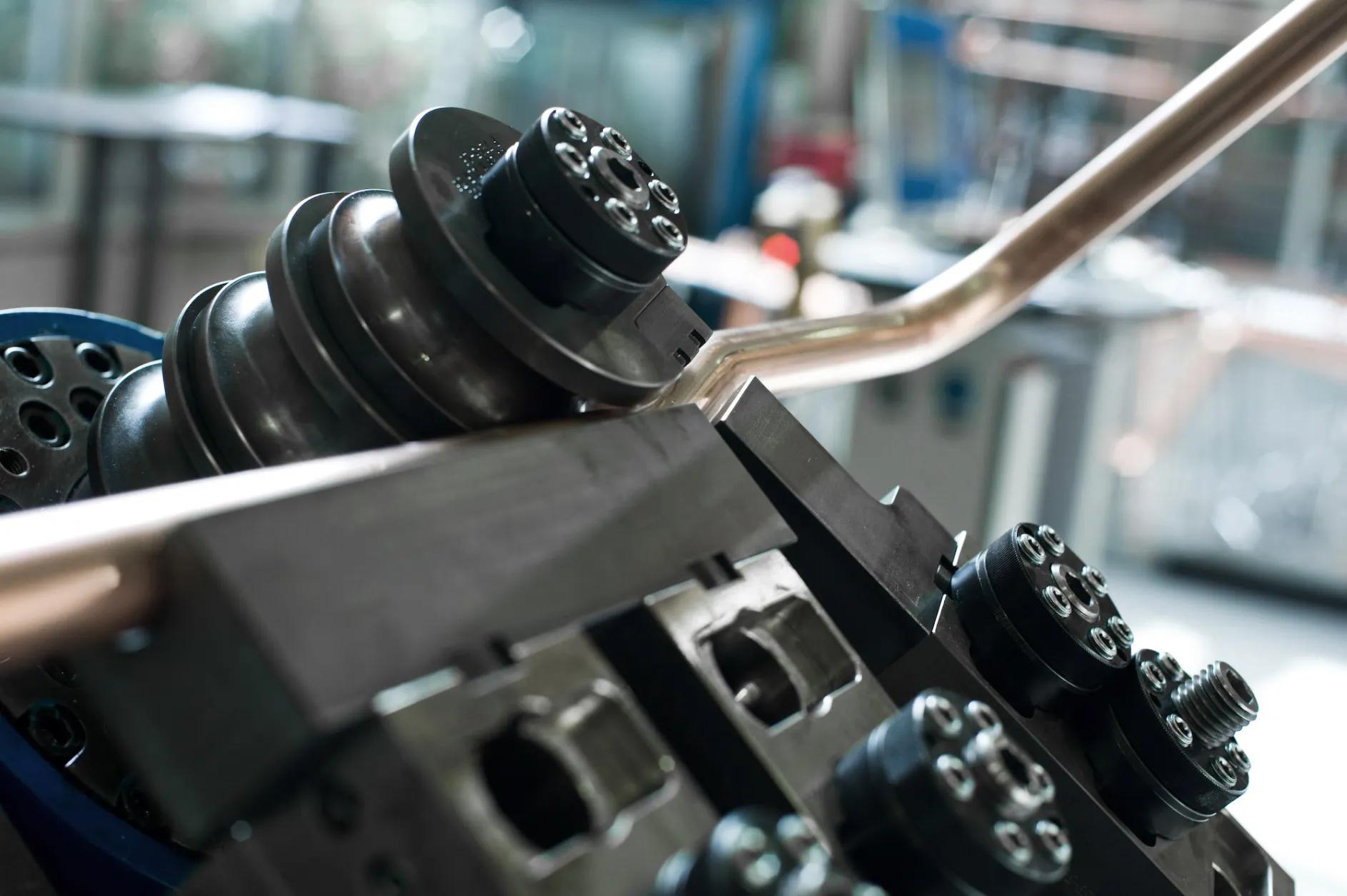

Approximately 120,000 tonnes of steel are processed every year in the over 90,000 square metre production area. The range of the technologies used extends from coil cutting, forming, roll forming, laser cutting, pipe bending, welding and coating to the assembly of the finished components. Embedded in a mature logistics concept, they are made available for delivery in accordance with the JIT/JIS method.

Precision work in forming, joining technology, coating and assembly ensure the outstanding quality of all products and processes. Our in-house engineering with toolmaking guarantees prompt and excellent solutions even in the product creation process. And then there is our decades of experience in this field. HÖRMANN Automotive in Gustavsburg is thus one of the leading manufacturers of forming-related products for the commercial vehicle industry in Europe.

HÖRMANN Automotive

Gustavsburg GmbH

Ginsheimer Straße 2

D-65462 Ginsheim-Gustavsburg

T +49 6134 588-0 • F +49 6134 588-501

info.gustavsburg@hoermann-automotive.com

Your Contact

Managing Director in Gustavsburg

Andreas Müller

Managing Director Technology & Innovation

Dr. Wolfram Schmitt

HÖRMANN Automotive St. Wendel GmbH

As a long-term partner of the agricultural and construction machinery industries, HÖRMANN Automotive St. Wendel GmbH develops, produces and delivers high-quality pressed components, which we also join and assemble to form ready-to-install modules, to all renowned manufacturers. The location is primarily specialised in the production of large flap systems and hot-formed pressed parts. Products for very special requirements are designed to suit the needs of our customers.

Components, modules and systems for the agricultural machinery industry

The employees produce top-quality components for agricultural machinery using state-of-the-art technologies and processes. Besides the usual bare or galvanised deep drawing steels, the employees are similarly experts when it comes to stainless steels, copper and aluminium. Sheet thicknesses of between 0.5 mm and 3 mm are formed as what are known as fine sheets. The wings for tractors and side trim parts for harvesting machines and tractors are given here as examples. Furthermore, thick plates of up to max. 8 mm are formed on presses with a pressing force of up to 16,000 kN into, for example, pedal levers, feed hoppers for harvesting machines or shields for exhaust systems.

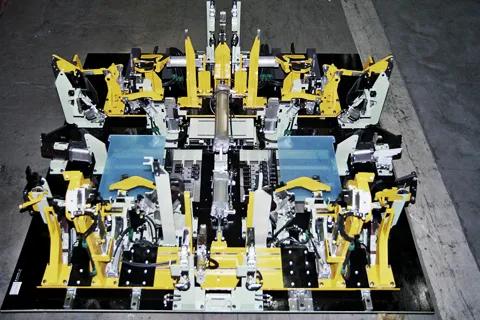

Welded parts are produced via manual or automated processes in the plant; these include outer skin panels for harvesting machines or steel bumpers for trucks as well as the basic pressed parts for the production of cabs for various agricultural commercial vehicles. Robot-automated press lines, state-of-the-art laser technology and CNC milling machines are used here in production.

Overall, HÖRMANN Automotive in St. Wendel produces around 300 different products for a total of 25 different customers from the field of agricultural and construction machinery and delivers directly worldwide. Our aspiration is excellence in development, production and logistics. With expertise and passion, the employees design products that combine all the advantages of design and function. All renowned, globally active agricultural machinery manufacturers benefit from this knowledge in cooperation based on partnership.

HÖRMANN Automotive St. Wendel GmbH

Essener Straße 3

D-66606 St. Wendel

T +49 6851 8005-300 • F +49 6851 8005-370

info.hat@hoermann-automotive.com

Your Contact

Technical Managing Director

Dipl-Ing. Martin Klein

From the idea up to series production

HÖRMANN Automotive ist in verschiedenen Branchen der Nutzfahrzeugindustrie unterwegs und verfügt über vielfältige Referenzen.

Referenzen

Rahmenlängsträger und Rahmenanbauteile für Truck

Rahmenlängsträger und Rahmenanbauteile für Truck

Hydrauliktanks für Baumaschinen

Kabinenteile für Traktoren

Medienführende Leitungen für Traktoren

Komponenten für Ladesäulen

Entwicklung, Betriebsmittelbau und Fertigung Rahmenlängsträger und Rahmenanbauteile sowie großflächige Feinblechkomponenten aus Stahl und Aluminium für MAN

Entwicklung, Betriebsmittelbau und Fertigung Rahmenlängsträger und Rahmenanbauteile sowie großflächige Feinblechkomponenten aus Stahl und Aluminium für DAF

Entwicklung, Betriebsmittelbau und Fertigung von Hydrauliktanks bis 1.600 Liter für Liebherr

Entwicklung, Betriebsmittelbau und Fertigung umgeformter, gelaserter, montierter und lackierter Klappensysteme für Claas JAGUAR

Entwicklung, Betriebsmittelbau und Fertigung umgeformter und gelaserter Serienbauteile für die 5R-Traktor-Serie von John Deere

Entwicklung und Fertigung von Komponenten für Ladesäulen von Wirelane

Produkte

Chassis

Body-in-White

Seitenverkleidungssysteme

Busdecken

Kraftstoff- und Hydraulik-Behälter

Schweißsysteme

Pressteile

Kraftstoff-und Kältemittel-Rohre

Aluverkleidungen und -klappen

Schweißkomponenten

Verpackung von Komponenten

Vorrichtungsbau

Wir bieten Fahrzeug-Chassisteile, Fahrzeug-Anbauteile, Oberflächentechnologien, produktionsspezifische Schnitt-, Biege- und Ziehwerkzeuge, Rahmen-Vormontage, Just-In-Sequence- und Modulbelieferungen.

Wir liefern alles, was die Karosserie-Außenhaut eines Automobils ausmacht.

Wir liefern lackierte und vormontierte Seitenverkleidungsteilen für Erntemaschinen, die "just-in-time" an das Hauptmontageband geliefert werden.

Produktion und einbaufertige Montage von Innenausstattungssystemen für Nutzfahrzeuge, insbesondere von Deckensystemen

Wir besitzen jahrzehntelange Erfahrung in der Herstellung von Kraftstoff- und Hydrauliktanks.

Wir fertigen komplette Fahrgestelle für Düngemittelfahrzeuge und neuerdings auch für einen Feldhäcksler.

Nach dem Bedarf unserer Kunden, die vorwiegend aus der Land- und Baumaschinentechnik kommen, konzipieren wir Produkte für ganz spezielle Anforderungen.

In der Fertigung von einbaufertigen Rohrsystemen für den Transport von Kraftstoffen und Kältemitteln in Bussen und PKW besitzen wir ein in jahrzehntelanger Tätigkeit erworbenes Fertigungswissen.

Die Fertigung von Kofferraum- und Tankklappen sowie Verkleidungen aus Aluminium für Busse und Nutzfahrzeuge gehört neben den Tanks zu unseren Kernkompetenzen.

Wir fertigen vorwiegend achstragende Fahrwerkteile verschiedener Komplexitätsgrade, die wir – zu Schweißbaugruppen und -komponenten montiert – direkt ans Band liefern.

Wir übernehmen die Gesamtverantwortung für die Verpackung und Lieferung von Ersatzteilen, CKD-Komponenten und Kit-Lösungen.

Wir planen und fertigen innovative Vorrichtungen, mit deren Hilfe die verschiedenen Einzelteile eines Endproduktes oder komplexerer Komponenten maßhaltig miteinander verschweißt werden können.

Arbeiten bei einer dynamischen Unternehmensgruppe

Wir sind ein attraktiver Arbeitgeber für engagierte und leistungsorientierte Mitarbeiter.